Industrial Springs Manufacturer

We are manufacturing all kind of Quality Industrial Springs like Clip, Hook, Lock, Valve and more spring in all accurate sizes.

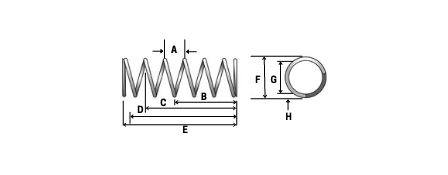

Rainbow Springs offers you a diverse product portfolio of high-quality compression springs with ground or unpolished spring ends. We produce, among other things, cylindrical wound compression springs, conical compression springs and barrel springs.

Cylindrical compression springs are by far the most commonly used. Here the customer has a large selection of materials for a wide variety of applications. In addition, the variety of uses can be expanded again with various surface treatments.

Conical compression springs offer relatively constant spring rates and are characterized by a shorter block length than cylindrical wound compression springs.

Compression springs store and transmit forces by compressing the spring ends. The force is introduced via the end turns. When the spring is released, the stored energy is partially released again. Compression springs are used in mechanical engineering, among other things, but also in many other areas, for example in chassis, electrical appliances, in ballpoint pens or in door closers.

Compression springs are used in countless applications and for a wide variety of requirements. We calculate the ideal spring dimensions for each individual application and select the appropriate spring material in terms of stress and environmental conditions.

Our compression springs are suitable for both static and highly dynamic applications and have ground or unhanded spring ends. We use state-of-the-art systems for grinding the spring ends, some with fully automatic feed and setting equipment. We also have the right technical equipment for cold setting, hot setting and for one hundred percent spring force control. All our production facilities are equipped with electronic measuring, control, and sorting devices. You can always expect the highest quality from us.

As the leading manufacture of compression springs, we only use selected materials that are subject to strict quality regulations. We have common materials in (almost) all dimensions in stock. We would be happy to advise you on the selection of the ideal material for your individual compression spring.

Round wire springs

Our compression springs made of round wire are used in all areas of machine, apparatus, fixture and plant engineering. They are the ideal components for storing forces and realizing return movements reliably and cost-effectively.

With our products we serve the niche where catalog goods no longer meet the given requirements. By selecting special materials from our family of materials, we regularly manage to find an ideal solution for our customers, even in extremely limited installation spaces.

compression springs are used in a wide variety of applications and products in a wide variety of industries including manufacturing, automotive, Transport, logistics, construction, mechanical engineering, agriculture and the chemical industry.

Compression springs are versatile and can be made in many shapes to meet specific needs. Typical applications for compression springs are electronics, industrial equipment, medical instruments / devices, toys, furniture, precision tools, mining and drilling equipment, notebooks, pens and many more. Of the many types of springs that Rainbow Spring Manufacturing offers, compression springs – are among the most commonly used metal springs.

Compression springs are ubiquitous in everyday life – and in many cases we are only aware of the presence of compression springs when we take a closer look at them.

We are manufacturing all kind of Quality Industrial Springs like Clip, Hook, Lock, Valve and more spring in all accurate sizes.

Tapered spring is also known as Conical Spring. It is often used as a contact spring & battery spring.

A tension spring is a cylindrical spiral spring that stores energy that is used by pulling force.

A compression spring is a cylindrical spiral spring that resists an axially applied pressure.

Torsion springs are used where a torque has to be generated or rotational energy has to be accumulated in a construction.

Die springs are preferably chosen for constructions where a very high force is required with limited installation dimensions.